Stud Welder and Stud Welding Technology

Stud Welder and Stud Welding Technology

(Chengdu Stud Welding Research Institute Chengdu 610051)

Summary: This article is a introduction of Stud welder, Stud welding technological parameter, a deep Analysis for the power supply of Arc stud welder, Stud penetration welding and the present situation of stud welding technology in China, a explanation of the developing trend of stud welding technology.

Keywords: Stud welder, Stud welding technology, Stud penetration welding, Stud welding development

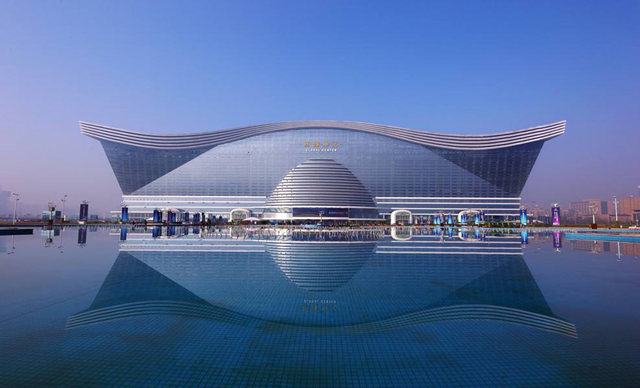

Stud welding is a method since 1918 which can generate electric arc between one end of stud and metal work-piece, exert pressure rapidly after the joint surface melted to make the welding finished. All countries value it Because of the features like fast, reliable, simple procedure, low cost etc. It is applied in bridge, highway, builds and constructions, ship building, automotive, power station, control cabinet by constant development and improvement especially after The World War II. Low carbon steel, stainless steel, low-alloy steel, copper, aluminum and other alloy Material of stud, shear connector, pin bolt, toggle pin etc can be welded by stud welding.

1 Category of Stud welder

Stud welder is divided into two categories: Arc stud welder and Capacitor discharge stud welder, the former is welded by the power of arc welding rectifier, the latter is welded by momentary discharge of capacitor stored energy.

The feature and application of two welding method showed in Table 1.

Tabel 1 Feature of Arc stud welding and Capacitor discharge stud welding

| Welding method |

Welding time (ms) |

Weldable stud diameter (mm) | Welding current (A) |

Protected Mode | Minimum plate thickness | |

| Arc stud welding |

Ferrule protection | >100 |

3~25 |

300~3000 | Ferrule | 1/4d Over1mm |

| Gas protection | >100 |

3~16 |

300~3000 | Gas |

1/4d Over1mm |

|

| Short-cycle welding | ≤100 |

3~12 |

≤1500 | No protection or Gas | 1/8d Over0.6mm |

|

| Capacitor discharge stud welding |

<10 |

3~10 |

≤3000 peak value) |

No protection | 1/10d Over0.5mm |

|

1.1 Arc stud welder

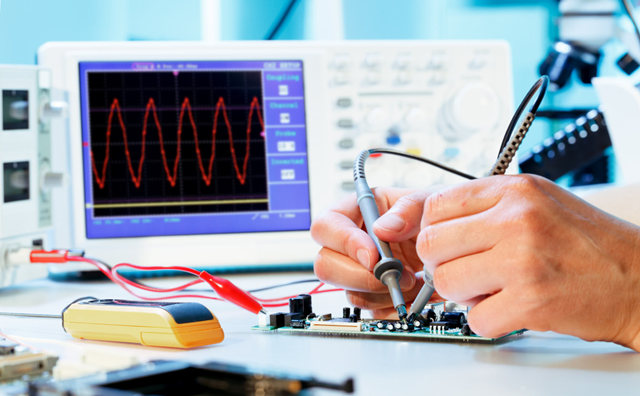

Arc stud welder is consisted of welding power, controller, welding gun, ground clamp, welding cable etc. Welding power and controller is merged into one of most welding machine which called host. The more advanced control mode is microprocessor, which can set precisely and control welding current and time in welding process timely. The welding power is arc welding rectifier which is controlled by thyristor or IGBT.

The feature of DC welding power of stud welding

a. The welding power should have declining static external characteristic to keep the arc stable and get good welding quality.

b. To ensure 100% arc strike success rate, the welding power should have arc strike current(40~50A) and superior floating voltage(70~100V). The floating voltage is even over 100V for big diameter stud welding. Only this can meet the request of larger lifting height.

c. The superior load voltage is necessary. According to the definition of declining welding power, the load voltage should keep 44V when the welding current ≥600A. The cable length of welder which used in construction site reaches 50 meters so the voltage decrease much. The welding capacity will be reduced if we don’t increase the load voltage. The situation will be more serious even failed welding if the cross section area of working cable is not comply with ISD14555. This is one of the main reason that the maximum diameter of weldable stud is different when the various factory produce same current grade welder.

d. Welding current must have a sharp rise edge. The biggest feature of stud welding is instantaneous large-current, so the welding current should reach peak value with 32ms after power-on. The rise time of welding current for Short cycle stud welding should be shorter otherwise the welding current still does not reach peak value when the welding time comes. The welding quality can not be guaranteed if the setting of welding current and the gained power of stud welding is out of proportion.

The only method to increase the rise speed of welding current is reduce the inductance of reactor. The reason why normal arc welding rectifier enlarge the reactor is not only hodrick-prescott filter but also limiting the rise speed and peak value of short-circuit current to reduce the stroke current when arc-striking, meanwhile to reduce splash and arc crater, avoid burning though the work-piece. However, stud welding is different because it is running as per the logical program of preset arc-striking, stud lifting and main power connecting. In other words, the main power is connected in the case of certain gap between stud and work-piece to avoid the splash when arc-striking. Actually the biggest “splash” of stud welding is the splash instantaneous when the stud inserted into the weld pool.

e. The power should have small internal impedance. Compare to temperature classification B, the temperature classification H of main circuit of welding machine is small volume and light weight. However, it is not perfect. GB11021 shows: The highest temperature of H and B is 180 ℃ and 130℃ respective. H class is 40% higher than B class. In other words, the current density can be increased drastically to reduce the cross-section area of wire, the impedance of electric circuit will be increased consequent. This is fatal flaw for the large current stud welder. If the insulation of main circuit changed from B class to H class, the increase of total resistance will be even 0.006 Ω because of the decrease of all wire cross-section area of subloop. Calculating against welding current 2500A, the additional capacity is 37.5kw, it is considerable if plus the initial increased consumption of main transformer. The increased consumption of main circuit of welding power will cause the decreased welding power and capacity, this is the price paid from small volume and light weight. That is to say, H class need more power than B class when welding same diameter stud. Our product RST-3150-3 stud welder use B class insulation which can weld d=30mm stud, the other same grade H class stud welder can not reach this level.

f. The supply Power Cabinet should have enough capacity. The low duty cycle(lower than 15%), low consumption of arc stud welder and large peak power(even over 300kw when welding big diameter stud) request enough capacity of power cabinet to satisfy the stud welding. The welding quality can not be ensured if the supply power is small(the decrease of power voltage is less the 15% of rating value and over the range of variable-voltage when welding). Some welders will be forced stopped according to the preset power voltage limit. The good way to solve this problem is setting up special line, increasing the capacity of power cabinet and escaping from power consumption peak.

1.2 Capacitor discharge stud welder

The feature of Capacitor discharge stud welder is short time, small thermal deformation, especially suit for stud welding on thin board, applied in shipbuilding, automotive, power cabinet and cupboard etc. The welder is fit for automatic production line because of its simple operation and no need for gas shield, applied in welding production line of automotive widely. The productivity of stud welding depends on the charging speed of capacitor, it can reach 15 pieces per minute(manual welding) and 30 pieces per minute(automatic welding).

There are two kinds of Capacitor discharge stud welder: arc-drawing and arc-striking. Arc-drawing Capacitor discharge stud welder is similar with Arc-drawing short cycle stud welding, the welding time is about 3~10ms as table 1. The feature of Arc-striking Capacitor discharge stud welder is the arc-striking point of weldable stud(two kinds: contact mode and gap mode) Contact mode stud welding time is ≤3ms, gap mode stud welding time is about 1ms. No need of gas shield even welding aluminum and other alloy. Capacitor discharge stud welding time can not be adjusted.

The welding power of Capacitor discharge stud welding depends on capacitance of capacitor and charging voltage. It can be calculated as following:

W= CU2

CU2

(1) Equation:W—Rated store energy of welder,J;

C—Total capacitance of capacitor bank, F;U—Charging voltage ,V。

The welding current peak value of Capacitor discharge stud welding is about 1000~10000A, depends on capacitance of capacitor, charging voltage and inductance&resistor of welding circuit. The charging voltage can not be over 200V for safety.

To protect personal and device safety, Capacitor discharge stud welder should have current limiting protection unit, constant-current charge unit and automatic discharge unit.

1.3. Welding polarity

Generally, “Direct Current Straight”(Stud connected to the negative pole of welding power, work-piece connected to positive pole) is adapted for welding black metal to increase the fusion penetration because the temperature of positive pole is higher than negative pole. “Direct Current Reversed Polarity”(Stud connected to the positive pole, work-piece connected to negative pole) is adapted for welding copper, aluminum and alloy to clear the oxide layer on the appearance of work-piece and improve welding quality by the bombarding atomization effect of positive ion. The polarity should all like the above when welding by Arc stud welder or Capacitor discharge stud welder.

2. Technological parameter of arc stud welding

The technological parameter of arc stud welding contains welding current, welding voltage, welding time, lift height, overhang length and insertion speed etc.

a. The welding current is about 300~3000A adjusted according to the diameter of stud. The welding current can be evaluated for Non-alloy Steel as following if the stud diameter is given2):

I(A)=80×d(mm) d≤16mm (2)

I(A)=90×d(mm) d>16mm (3)

The welding current is 10% less than the calculated value as above equation.

The welding current of short cycle arc stud welding(600~1500A) is fixed and related with the power supply. So the welding power depends on the welding time only.

b. The relationship of electric arc voltage and welding current is decided by static external characteristic of welding power. Electric arc voltage(value is 20~40V usually) is up to the lift height and welding current. The oil and grease on the appearance of work-piece will increase arc voltage, inert-gas will decrease arc voltage.

For flat welding(the welding plane of work-piece parallel to the ground plane), the welding time can be evaluated as following:

tw(s)=0.02×d(mm) d≤12mm (4)

tw(s)=0.04×d(mm) d >12mm (5)

The welding time should be decreased for horizontal welding(the welding plane of work-piece normal to the ground plane). The short cycle welding time is less than 100ms, which not only depends on stud diameter, but also is related with current strength.

c. The lift height of stud is proportional to stud diameter, about 1.5~7mm. Lift height can avoid the arc stability effect and ensure weld seam quality when excessive molten drop lead to short-circuiting. Keep the arc stability and supply enough power to weld seam is crucial because the temperature of arc column is much higher than negative pole or positive pole. When penetration welding, to get nice joint, the lift height must be increased to burn through the galvanized sheet by high temperature from electric arc. Of course there are disadvantages of lift height: increasing the length of electric arc cause the magnetic blow; increasing the air hole of weld seam.

d. The overhang length of stud is proportional to stud diameter about 1~8mm. It is related with request shape of welding foot around the welding seam when ferrule protection. The overhang length should be increased when the welding foot is requested to be high and wide; decreased conversely. The overhang length of stud should be a little longer than the molten length of stud. The stable electric arc can not be generated and lot of metal splash with slag defect if the overhang length value is designed too long. On the contrary, the melting quantity will be less and the shape of weld seam will be defective if the the value is too short.

e. The method of inserting stud to molten pool is extrusion. To shape nice welding joint, the molten deleterious impurities would be extruded from weld seam before the instant of weld seam shaped. However, to avoid lot of splash, the insertion speed should not be too fast.

The insertion speed of stud: d≤14mm,200mm/s;d >14mm, 100mm/s

The function of adjustable damping of welding gun can meet above request. When welding big diameter stud, the insertion speed should be slow to decrease the splash because the melting quantity is proportional to overhang length and diameter.

Welding current, welding time, lift height, overhang length are the main technological parameters of arc stud welding which should be set according to the stud diameter and work-piece material. The technological parameters are not all identical when using different factories’ welders even for same stud diameter. The most suitable technological parameters must be chosen after many times test welding and evaluation of appearance&shape of weld seam, post-weld height of stud and mechanical properties(drawing, hammering, bending, twisting etc).

Related recommendations